Halo: From Factory to Track. How is it made?

What requirements must a Halo meet to be fitted on single-seaters worldwide?

A long and rigorous process to ensure maximum safety and quality for the drivers

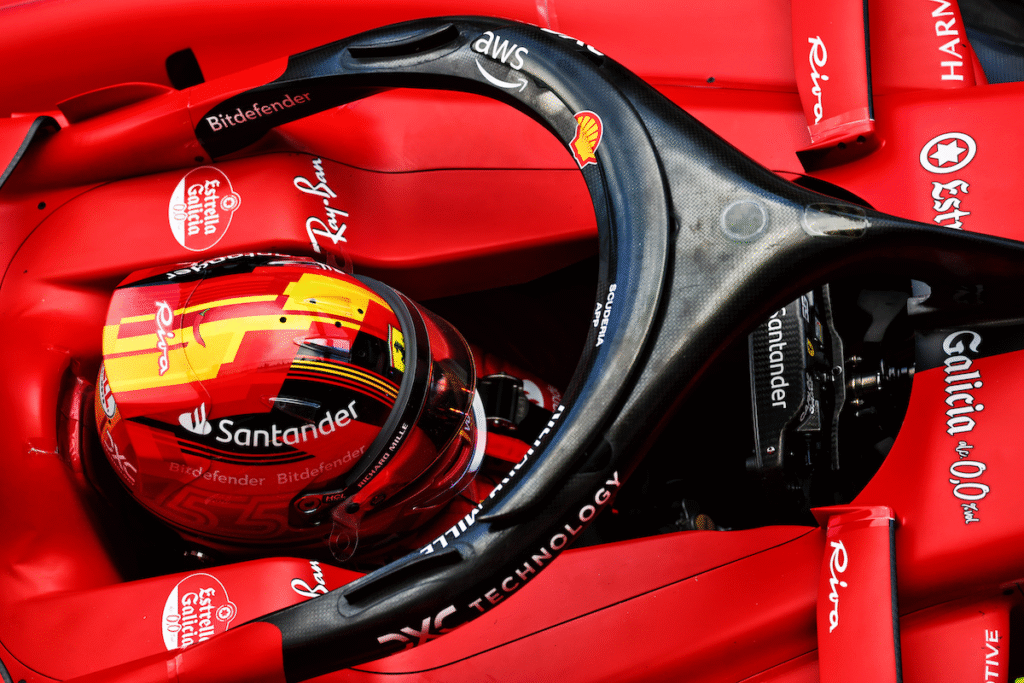

Officially introduced in Formula 1 in 2018, the Halo safety device has become a key element in protecting drivers. Since then, it has been progressively adopted across all junior categories and major FIA championships.

It is designed to safeguard the driver’s head from flying debris, loose wheels, or direct impacts against barriers during crashes. But what makes it so effective?

The structure is made from Grade 5 titanium (Ti-6Al-4V), an aerospace-grade alloy known for its exceptional strength-to-weight ratio. It features an inverted U-shape with three mounting arms: two on the sides and one central pillar that connects to the chassis directly in front of the driver’s eyes.

This configuration is built to absorb and deflect massive impact forces without obstructing the driver’s vision or movement. It is is firmly attached to the chassis and, thanks to its materials and design, it can withstand loads of over 12 tonnes, serving as a vital shield in high-risk situations.

The Weight

The Halo weighs between 7 and 9 kg, including its mounting components, depending on the version and updates. The earlier versions were slightly lighter, but over time, the FIA has strengthened the structure, adding almost 2 kg to improve overall safety and resistance under extreme conditions.

Extreme impact resistance

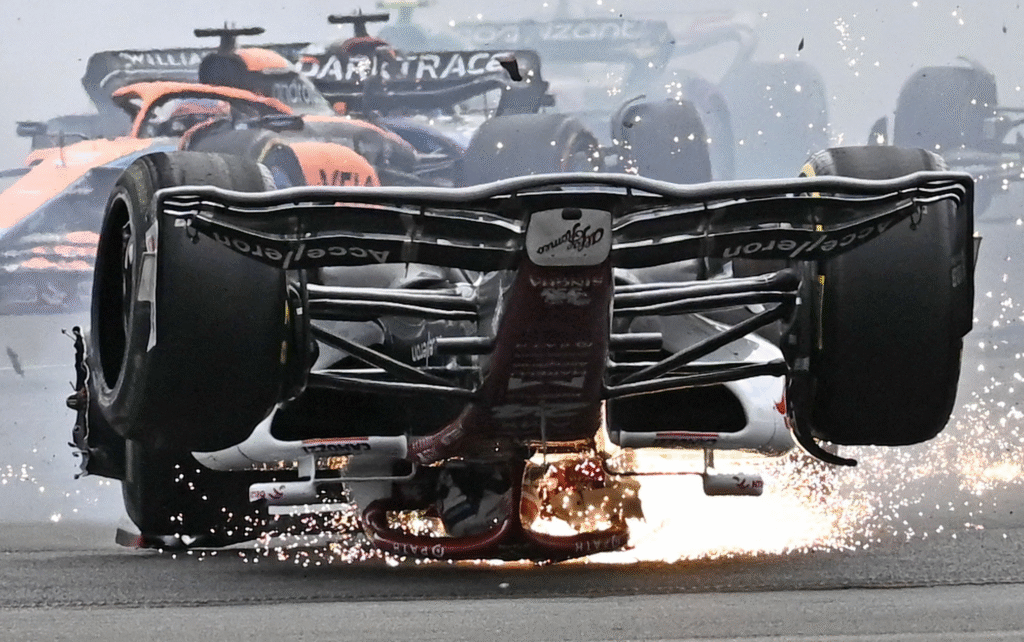

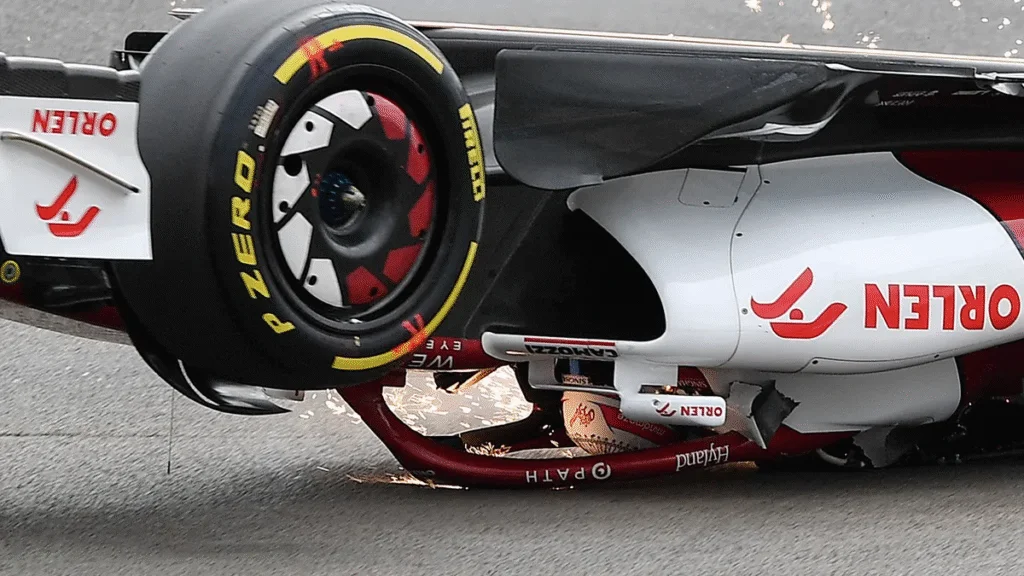

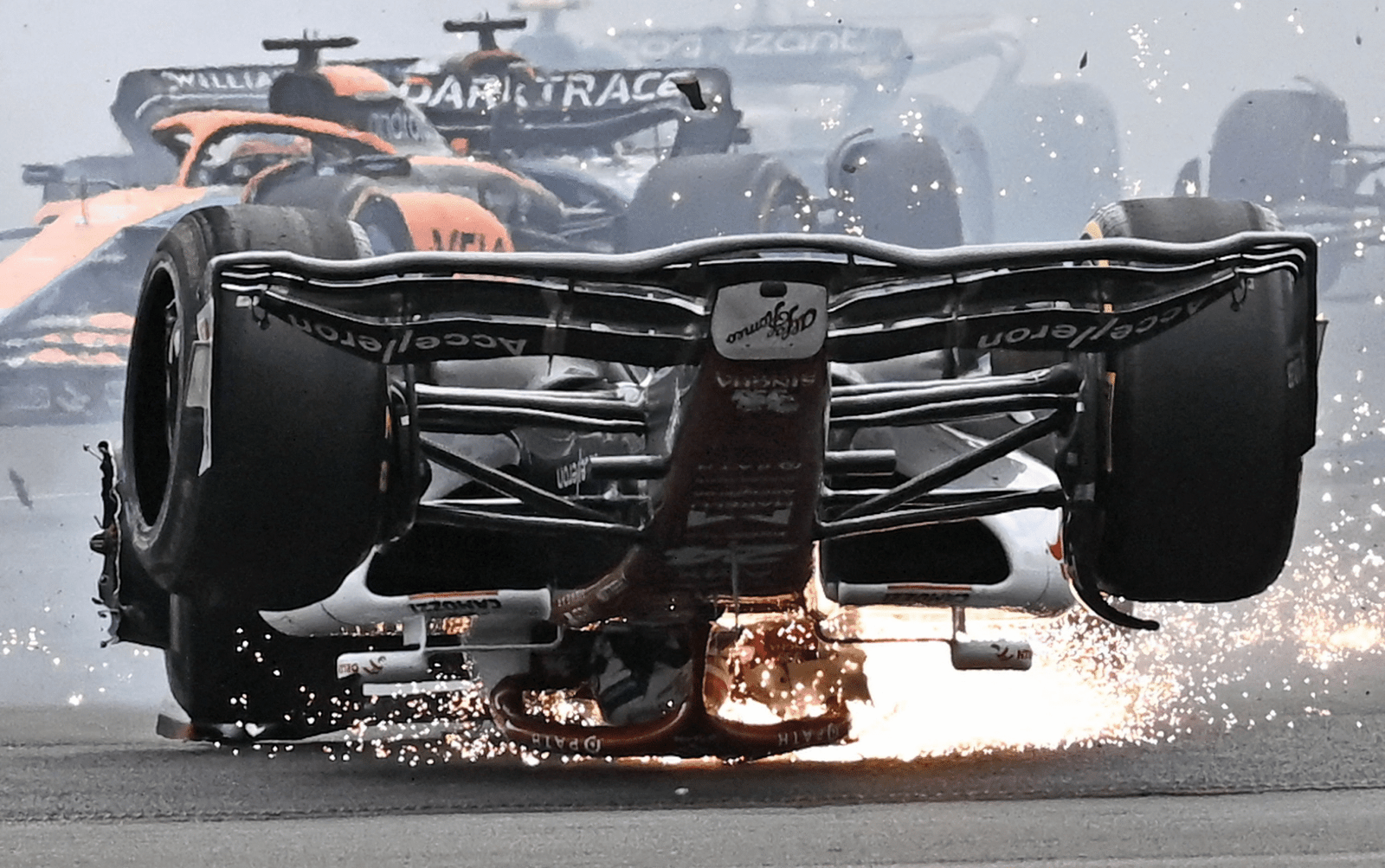

Halo is designed to withstand extreme loads, including a vertical static weight of around 12 tonnes—roughly equivalent to a London double-decker bus—and the impact of a 20 kg wheel traveling at 225 km/h. According to FIA simulations, the device increases a driver’s chance of survival by 17% in serious crashes. It must pass tests that apply forces up to 125 kN in multiple directions—about 15 times the weight of a Formula 1 car (800 kg).

All these specifications are standardized by the FIA to ensure consistent performance and safety across all racing categories that use the Halo.

Halo, Strenght and safety requirements

It is not manufactured by the racing teams themselves, but by FIA-approved external suppliers that follow strict safety and quality standards. As of today, there are only four homologated manufacturers:

- CP Tech GmbH – the first supplier approved by the FIA, responsible for producing Halo devices used in F1, F2, and Formula E.

- SS Tube Technology (SSTT) – based in the United Kingdom, specialized in advanced tubing systems.

- Dallara – the renowned Italian chassis manufacturer, a major name across various motorsport series.

- V System – another certified producer contributing to the global supply of this critical safety device.

We previously covered a real-life example of the Halo’s life-saving impact — you can find the full story in the article linked below.

Carved from a Solid Block of Titanium

The Halo is made from a single bar of aerospace-grade titanium, weighing around 10–12 kg. The manufacturing process uses CNC (Computer Numerical Control) machining to carve the component from a single solid piece, eliminating any joints or welds. This method significantly increases the structural integrity of the Halo, making it more resistant to extreme forces and impacts.

Subjected to Destructive Testing

Each homologated model must pass extremely rigorous static and dynamic tests. Some of these are destructive tests, specifically designed to push the component to the point of failure. This allows engineers to accurately assess the true limits and structural integrity of the Halo under extreme stress conditions.

Heat-Resistant Coating

To protect the titanium from weather exposure, heat, and constant vibrations, the Halo receives a special surface treatment, such as ceramic coating or anodization. This enhances both its durability and performance under the extreme conditions typical of motorsport environments.

Each Unit Has a Serial Number

Every Halo is marked with a unique serial number and tracked by the FIA. This ensures it has been produced by a certified supplier and has passed all quality control checks. The installation onto the chassis follows a standardized and reinforced process, executed with millimetric precision. Teams are required to adapt the chassis structure to accommodate the Halo, complying with specific deformation and integration criteria set by the FIA.

A single Halo costs approximately €15,000–20,000 for Formula 1 teams. The price may vary slightly depending on the manufacturer and agreements with FIA-approved suppliers. This cost includes titanium machining, surface treatments, and quality testing. Some teams order multiple units for the entire season, typically 2 to 3 per driver.

Post Comment